At construction sites and warehouses, safety is the topmost priority. But it doesn’t just occur on its own. It needs certain steps to be taken. The three key elements ensuring the above factors are a commitment to protection from manufacturers, aerial lift training program, and a trained professional– safety manager who will help to make it all happen.

In this article, we have gathered four types of aerial lifts that mandate driver training while working on various sites and projects.

Aerial Lift Certification!

Workers must be capable of recognizing the threats and hazards bounded with the lift and should know how to avoid them. They must have Aerial lift certification where they will gain the expertise of how to prevent fatalities and injuries on work sites.

Training must consist:

- How to drive the lift.

- Methods to control fall hazards.

- Electrical threats like overhead power-transmission lines.

- Ways to save people standing below the falling objects.

- The lift capacity to carry loads.

Vehicle-Mounted Elevation and Rotational Lifts

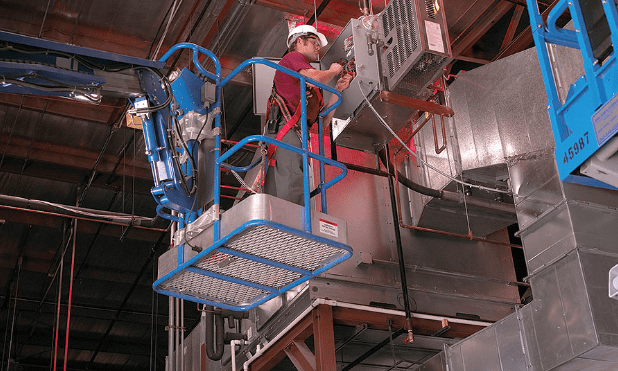

Lift Platforms after baskets and buckets must have mid-rails, guardrails, and toeboards. Lift operators must use a safety system that can protect them from falling like a body harness when on the platform.

A body belt or a harness is very important when the worker is at a specific height. The lanyard should be short enough and attached to the designated anchor point, so that workers cannot be dropped out of the platform. And when it is used, the aerial lift must be able to combat the lateral and vertical loads of a captured fall.

Workers should stand straight on the platform all time of working and avoid sitting or climbing on the edge or rail of the basket. The manufacturer’s instruction manual must be there with the equipment, and should be followed by all lift drivers and workers present at the worksite.

Boom-Supported Work Platforms

In this type of lift platform, it must have guardrails 42 inches high; while toeboards and mid-rails for at least four inches high.

While workers are on the lift platform, they should make sure that guardrails are lodged according to the manufacturer’s guidelines and access gates must be closed.

While the aerial lifts are so useful, it can get life-threatening for you if you are ignoring the protocols. Operate the piece of equipment only if you are trained and certified.

Do not forget to inspect the equipment and work area before using it. Follow a safe-work approach rather than being in a rush. Be careful, especially if you are around power lines.

Self-Propelled Work Platforms and Scissor Lifts

Inspect the lift before taking it to the work area. Make sure that the signs and instructions are clearly readable on the equipment manual. You must have the proficiency on lift operations so that you know when to lower the machine in emergencies.

Do not take the risk of using them if they have flaws and defects. Do not move the equipment when the elevation is on, or if you feel the intense wind. Inform your supervisor if you anticipate any hazard.

Manually Propelled Elevating Work Platforms

First thing first, never move the lift having the worker standing on it. Strictly follow the instructions applying on a construction site to know exactly how to work safely. Report your supervisor if the equipment needs repairs and maintenance.

You must cooperate with other co-workers and be aware if multiple tasks are taking place simultaneously. Carelessness while using lifts is a serious matter, as it may result in life-threatening actions.

Conclusion

Aerial lift training programs must be evaluated annually. This is the only way to work on any job site efficiently. And, it is also beneficial in identifying the defects in the lifts; develop skillful drivers and more accurate action plans!