The last fifty years have been heaven when it comes to technological advancements. The most we’ve felt is through the Internet because we got connected to people all around the world. However, that’s not the only industry that has evolved.

Science is a large domain, and there has been significant progress in chemical exposure, high-temperature protection, electrical resistance and conductivity, abrasion, particle erosion, and barriers. All of these fields have advanced substantially due to thermal spray coating. Click here to read more.

That’s because we discovered how to coat any kind of material, and we can do it with anything we like. This might seem a bit useless, but there are tons of different benefits that come out of this. The main one is improving the capacity as well as the productivity of components.

The planet has a limited number of resources, and there’s also a set number of things that can be repaired and recycled. When you use a spray to improve the features of an object, you can include properties that better the materials tenfold.

What are the best features?

First of all, you can have a combination of coating and base materials. This is incredibly important since there is a limited amount of raw materials. Think about it. When a plane needs to be built, all of the parts aren’t made from a single type of metal.

Instead, it’s a combination of them that gives it the strength to take off, as well as being light enough so the motors can handle the weight. These industry-specific materials cost a lot, and by spraying the surface of an object, you can add properties that would cost a lot more.

Plus, if some part gets damaged or scraped, it’s much easier to repair it. Let’s take the plane example again. If a part of the wing gets damaged, the company would have to call someone to cut out the metal and replace it with a new part. Follow this link for more info https://3dprintingindustry.com/news/researchers-add-graphene-to-increase-strength-and-of-3d-printed-copper-184100/.

But that only makes that spot weaker since it has been replaced. Thermal coating systems serve as a way to fix problems in a relatively fast timeframe, and the practices are so good that they can repair high-grade worn parts without a difference to other refurbishing methods.

What are some processes that are widely used?

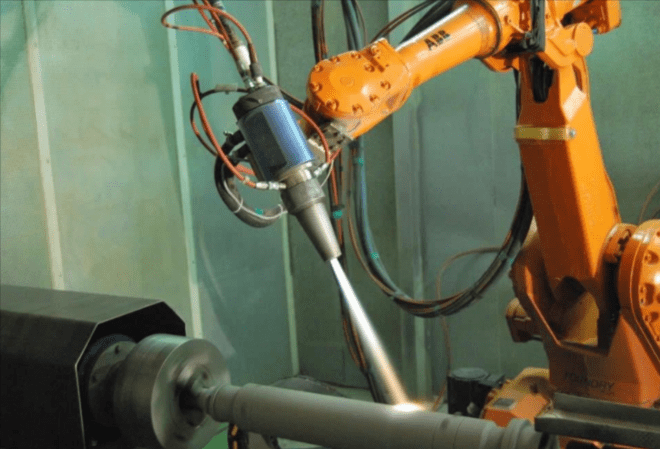

The first one on the list is high-velocity oxy-fuel spraying. The name might throw you off, but the process is quite simple and easy. During HVOF, a torch is used, and the nozzle is directed to the part that needs to be coated.

Inside the mechanism, the coating material is heated up, and the flame spreads out and makes the particles accelerate. Since the particles are moving quite fast, this creates a very thin layer on top of the surface, but it’s evenly applied. The main properties are strength and corrosion resistance.

However, the only downside to HVOF is that it doesn’t work well if the coated part is put under extreme temperatures. Next on the list is combustion flame spraying. This is a low-cost thermal spray alternative to HVOF. It works in almost the same manner as the previous process, and the only difference is that the flame has a lower velocity.

This is mainly because it’s powered by a mixture of fuel and oxygen, and that is why these coatings can’t handle a lot of stress. Finally, there are plasma and vacuum spraying techniques. The first one uses a plasma torch to both heat and spray.

It uses a powdered version of the main material, and it melts it by heating it up to an extreme temperature. Then it proceeds to work in the same way as a combustion torch, but the layer can be extremely thick, up to ten millimeters.

There are some companies that offer ceramics and metals instead of powder, and this is one of the most popular processes because it can be used pretty much anywhere. Lastly, the vacuum process must be used in a special environment, and the temperature needs to be cool in order for it to work.

This method is largely used in the automobile industry to coat bumpers, door mirrors, and dashboards. It’s more expensive, but it always gets the job done.